Whereas from massive manufacturing units to small polymer product, producers are constantly appealed to start on consistent environment friendly material recycling procedures; the impressing announcement of Chris Keehner, president of the renowned DS Pipe & Steel Supply LLC Maryland is truly inspiring. In a popular social media site, this renowned business personality reveals that out of the total steel produce every year, more than 40% production is now coming from recycling of wide-ranging steel scraps. This makes steel as one of the most recycled materials today. The man behind the growth of DS Pipe & Steel says that the growing amount of structural steel items these days are being used widely in construction and related industrial purposes.

Chris Keehner states in his blog that near about 88% of recycled materials are used in constructional activities. The scrap metals used include items like train tracks, broken and old cars, weightlifting items, steel portions of old refrigerators, washing machines whereas traditional iron beams are well accepted. You must be aware that earlier, the only way of steel production as well its raw material was heaps of lifted iron ore from mines. However, with the advanced techniques for last 150 years all big steel producers have embarked on employing recycling methods of scrap metals.

Benefits of Steel Recycling

- It is less expensive

- Overhead cost towards removal of iron ore from mines is reduced

- The process leads to lessening of ecological imbalance.

- Recycling of scrap steel is proved to be eco-friendly.

Chris Keehner further informs that as per studies, this has been found that recycling of steel and ferrous metals help lessen emission of CO2 @ 58%. Notably, the procedure eliminates 86% of air pollutants in contrast to ore mining. With this, very naturally, the use of water has also come down. Chris Keener, president of DS Steel welcomes his readers to have an access to his blogs and interesting posts through major social media sites. You will get to know everything you should be about the steel industry.

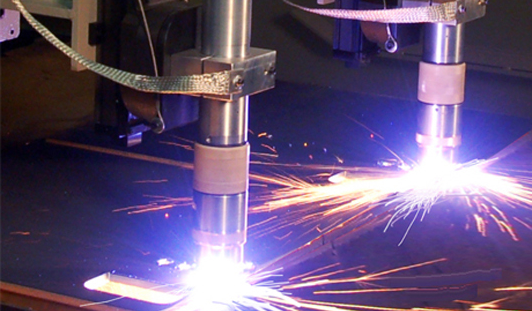

DS Is Equipped With Latest Plasma Cutting Techniques

Led by Christopher Keehner, DS Pipe & Steel Supply LLC is now identified as one of the leading suppliers of wide range of steel products and pipes of various types across Maryland and its neighboring states. Clients of this steel producing company would be impressed to learn that DS employs the most sophisticated plasma burning mechanisms and technology to offer clients with the accurate measurement of steel plates regardless of thickness factor. While accuracy of steel plate’s measurement is an essential factor no matter, whether it’s big company like shipbuilding, construction or producers of fabrication items, with plasma burning techniques DS can supply 100% error-free specifications.

The procedure entails use blend of highly packed air and electricity, blown at a very high speed by means of a nozzle. This generates a laser like element called as plasma and that melts the metal and cut the same. Huge plasma machinery items demands high-frequency, voltage spark to undergo the procedure. In order to initiate the process the company makes use of superlative class CNC or computer numerical-controlled cutting machinery. This ensures accuracy of material supplied based upon customers requirement. Whatever may be the thickness of steel plate, plasma cutting technology has been proved successful.