The roots of industrial compressors

The most ancient type of air compressor is the bellows, which was used in metalworking by blacksmiths for many centuries, perhaps even millennia, before the industrial revolution changed manufacturing and tradeswork forever.

The ancient Romans’ metalworking facilities used an early air compression device to fuel their fires, but it was the same technology on a larger scale: an apparatus that trapped a large volume of air, and then allowed it to be pushed out at a higher velocity and pressure, powered by human strength.

A precursor to the industrial compressor

In 1650, a German scientist named Otto von Guericke invented an air compressor/vacuum pump to assist him in his experiments. A simple mechanical device with a cylinder and a piston, it helped him to illustrate that fires can’t burn without air, people can’t breathe without air, and everything wants to fill a vacuum.

In a famous demonstration, he used his compression pump to remove the air from between two hollow spherical hemispheres, and had horses pull them in opposite directions. They didn’t budge until he allowed air to fill the vacuum. Then, they simply fell away from each other.

Von Guericke’s vacuum pump influenced the development of steam engines, which fueled nineteenth century industry.

The industrial compressor in mining

The first automatic air compressor was invented by Englishman George Medhurst for use in mining. Several refinements and new applications were developed during the industrial revolution.

Air compressors were used to dislodge rocks in mining and tunneling operations, and they were also used to keep working tunnels and mines free of water and slurry. By the late nineteenth century, the technology had been applied to compressed water, and hydraulic rams were being perfected.

In the mid-twentieth century, Mount Rushmore was carved using air compression-driven rock drills. Industrial compressors are still being used in tunnelling and mining operations today.

The industrial compressor in industry

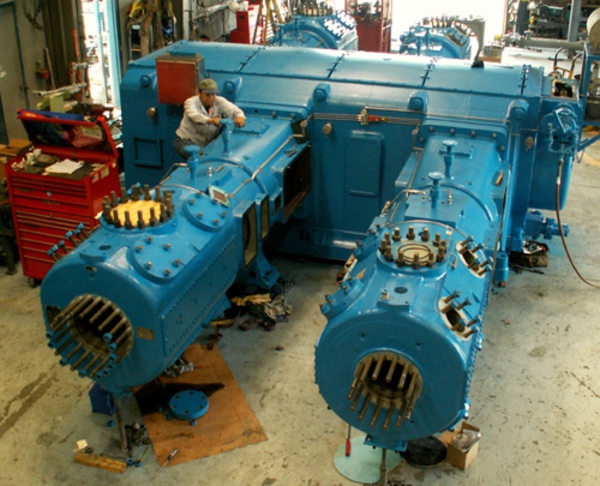

Since the beginning of the twentieth century, many specialized designs and new applications for compressors have developed. Pneumatic drills and hammers were invented in the late nineteenth and early twentieth centuries, and helped to drive twentieth century building and manufacturing. In the mid-twentieth century, centrifugal, axial flow, and screw compressors came into use.

Today, compressors are used to change the state of the refrigerant in air conditioning systems. The air compression systems in modern blast furnaces are the successors of blacksmiths’ bellows. Jet airplanes are propelled by compressors.

Many common industrial tools and processes are driven by air compressors. Air compressors can create the explosive force needed to insert a nail, power a jackhammer, or drill a hole in a sheet of steel, and they play a variety of important roles in construction and manufacturing.

Allight Sykes has one of the best ranges of industrial compressors in Australia. They’ve forged strong partnerships with manufacturers over the years so you can trust in their brand.