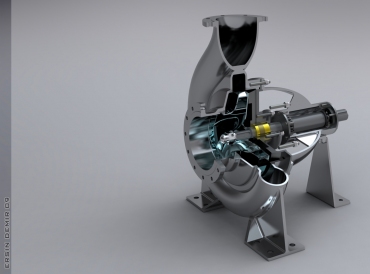

Centrifugal pump is a mechanical device which transforms input power to kinetic energy through acceleration of liquid in an impeller. It operates through centrifugal force which spins the liquid outside; from the eye of the revolving device (the impeller) where it enters into the inlet (the casing) as a low pressure area is formed causing more liquid to enter into the casing. As blades of this revolving device are curved it pushes off the fluid in a tangential direction through centrifugal force. The transformation of the energy to the fluid is proportional to the velocity at the fringe of the impeller. Familiar uses include water pumping like deep-well application, sewage, petroleum pumping etc.

Advantages of Using Pumps

One of the biggest advantages of centrifugal pump is that they are simple in nature so they can be easily produced by a variety of materials as the requirement of valves is almost absent. As the Centrifugal pumps moves at high speed minimal maintenance is required. These pumps also offer steady and firm input. In comparison to any other pumps these pumps are very cost effective as they require almost zero maintenance. As compared to any other pump these pumps are smaller in size. Centrifugal pumps provide lot of flexible space as they are easily movable

Utility of Such Pumps

The Centrifugal pumps function is the conversion of mechanical energy into flow, speed and pressure that is hydraulic energy. The general power of centrifugal pumps centers round mechanical, volumetric and hydraulic efficiency. Hydraulic efficiency is the most important of these factors. The power necessary for the pump to operate is proportional to the flow that it produces but it is non proportional to hydraulic efficiency. So selection of the most efficient centrifugal pumps reduces the cost of electricity.

Maintenance of Pumps

Centrifugal pumps consist of different kind of bearings and stuffing containers which require regular maintenance. The release stop valve must be closed before operating the pump .It works against the sealed discharge and which helps in creating a powerful pressure head before trying to push off and move the liquid downstream. The centrifugal pumps gains speed thus releasing the discharge valve and the pump sustains the pressure head unless there is a change in the state of operation. When the pump is operated with discharge closed the danger of hydraulicking is nil. So for a proper functioning of the pumps maintenance schedule and manufacture’s direction are always mandatory. Take care of such a device.